|

DC BRUSHED ROTARY MOTOR

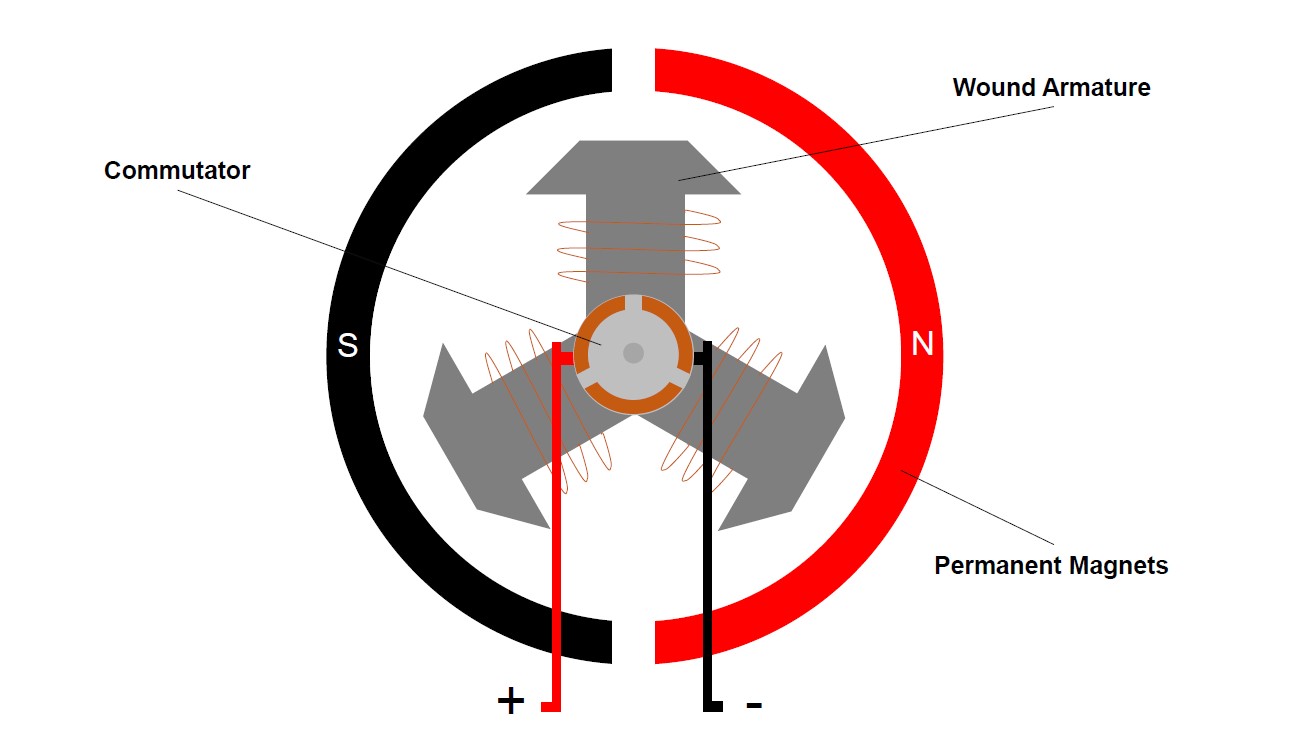

A DC brushed rotary motor is an electrical motor that powered by direct current electric power and converts electrical energy into mechanical energy. It contains a brushed internal mechanical commutation to reverse motor windings' current in synchronism with rotation.

To transfer current, brushed DC motor needs a mechanical system. A wound armature is attached to the center as a rotor, and permanent magnets are bonded to be a ring surrounding the rotor as a stator. The brushes (two small columns), pressed by spring pressure, are fixed on two specific positions and connected to the commutator, allowing the current to flow into the wound armature.

When the coil is powered, the magnetic fields are generated around the armature and the force then starts to rotate the motor shaft. The rotor coils and commutator rotate, while the stator magnets and brushes fixed. To avoid stopping when armature is horizontally aligned and the torque is zero, the commutator switches direction of current through the coil as the rotor turns, reversing the magnetic fields, and keeping the force in the same direction.

|