Product News: SANMOTION C S200 Motion Controller

SANYO DENKI Develops SANMOTION CS200 Motion Controller for IoT-Based Remote Monitoring and Maintenance of Equipment.

Sanyo Denki has developed and launched the SANMOTION C S200 motion controller that can remotely perform monitoring and maintenance of equipment. This controller can control motors while monitoring equipment status in real time. It contributes to improving the productivity and quality of various robots and production equipment. The lineup is available in a highly functional type that can control robots and electronic cams and a type specialized for PTP (Point-to-Point) motion.* Complex motion control and robot control can be performed at the same time as I/O signal control.

E-Motion America Inc. supplies our customers with Sanyo Denki New SANMOTION C S200 Motion Cotroller. They are suitable for Robots, conveying machines, facility equipment, automated equipment for agriculture and fishing

Features

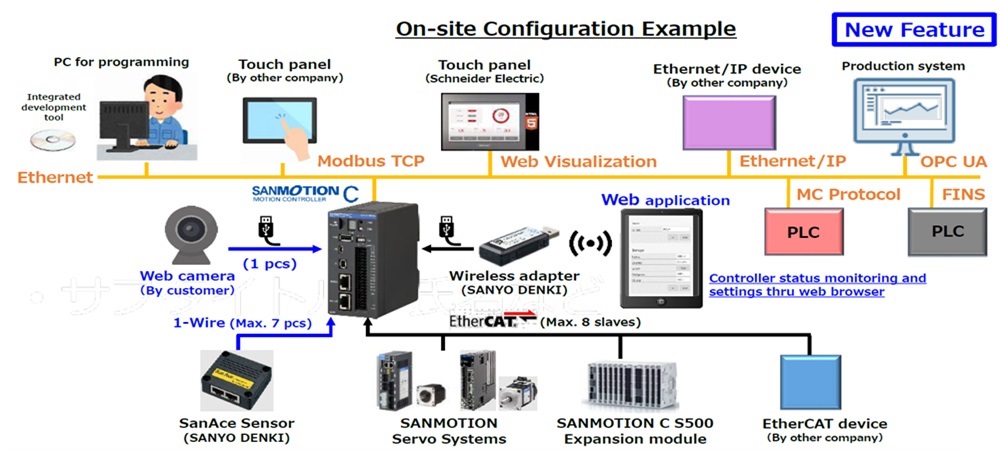

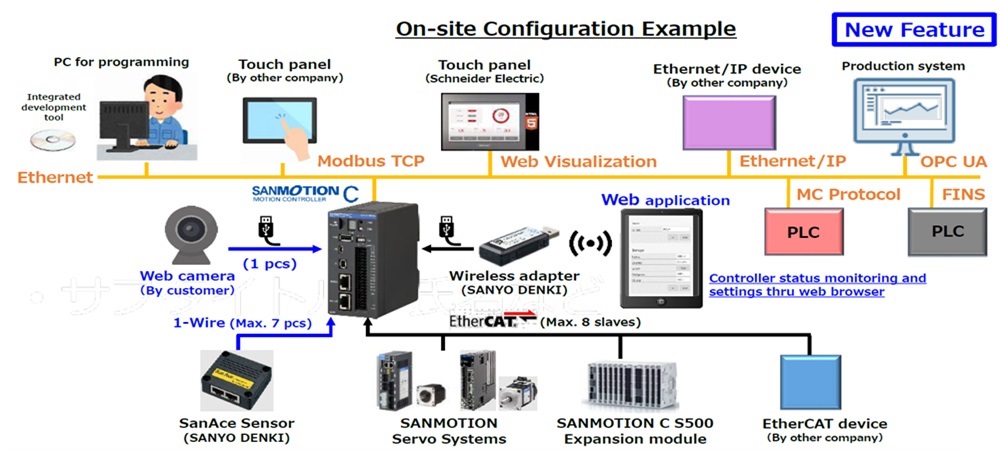

1. System Configuration

- This controller supports local configuration and remote configuration

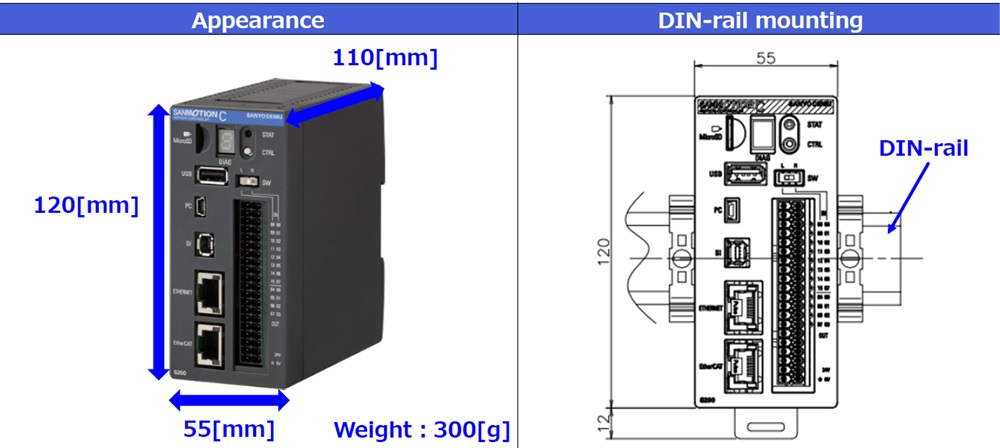

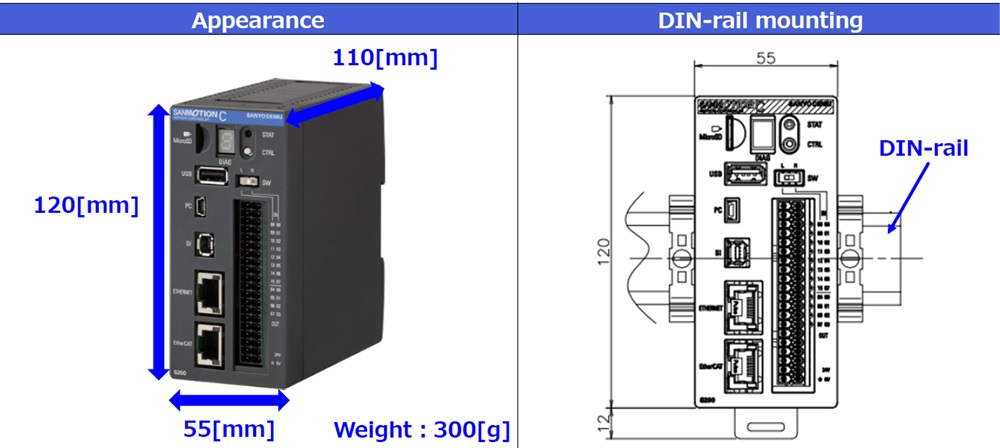

2. Compact Size

- This is a compact motion controller, saves space in control panel.Dimensions:120 mm (H) × 55 mm (W) × 110 mm (D), Weight: 300g.

3. High-speed EtherCAT fieldbus

- The new controller supports EtherCAT I/F which reduces wiring to optimize system configuration. Wire-saving: Reduces wiring to save system costs.

- Supports various kinds of devices: Besides our servo systems products, SANMOTIONG,SANMOTIONR servo amplifier and ModelNo.PB drivers, the new controller also supports EtherCAT products from other companies. Customers can choose the optimal products that suit their system.

4.Various control functions

- SANMOTION C performs three types of control: motion control, robot control, and sequence control.

- Single-axis PTP control and multiple-axis synchronous control can be freely programmed with electronic camming.

- CNC function: Uses G code in CNC editor to perform robot control. Controllable configurations are cartesian, SCARA and delta robot.

5. Multiple network functions

- Multiple network functions for various kinds of information exchange: The new controller comes with networks such as EtherCAT, Ethernet/IP, Modbus TCP and OPC UA. This allows the controller to collect and exchange real time information, that enables automation in manufacturing plants and system configuration utilizing IoT technology.

- Draws in HMI screen: Users can draw in the HMI screen in web browser using the integrated development tool. Program development using special software provided by touch panel supplier is not necessary.

- Displays HMI screen on a web browser: Drawn screens can be checked from web browser on users’ computer or smart device

6. Monitoring by camera

- Simple connection to web camera: Users can check images around the equipment via web browsers or save images to built-in memory or Micro SD card via .

- Still image recording function: Still images can be recorded in 100 ms intervals, and saved in the built-in memory or MicroSD card.

- Videos and still images: This controller supports the function of acquiring web camera video and still images on the same network.

7. Collects and records equipment data

- Servo system and environmental (temperature, humidity) data in time series are saved in CSV format. SanAce sensor module and SANMOTION C expansion modules are available for environmental data collection.

- Users can analyze data together with still images recorded to find out causes efficiently when abnormalities happens.

8. Email notification function

- Users in remote area will be notified by emails in real time when abnormalities occur in equipment. Emails are sent to designated addresses at the timing instructed by the program.

9. Remote operation of controller

- Remotely modify and monitor programs.

- Remotely check the status of your device

- New controller is equipped with web application that allows users to change controller settings remotely.

10. Connect to the cloud

- New controller is equipped with MQTT protocol for connection to user’s cloud system.

Product Lineup

| Model no. | SMC200-A | SMC200-B |

Interface | EtherCAT (100 Mbps), master function (FoE-compatible) |

Ethernet (10/100/1000 Mbps)

Protocols (Modbus TCP, OPC UA, Ethernet/IP) |

| RS-485 (9600 to 115200 bps) |

| 1-wire |

| MicroSD (for data storage of up to 32 GB) |

| USB 2.0 (for memory storage) |

Digital I/O | Digital input: 16 points, 24 VDC, positive/negative common input

Digital output: 8 points, 24 VDC, 0.5 A, sink output

Analog output: 2 points, 4 to 20 mA, current output |

| Input voltage | 24 VDC (19.2 to 30 VDC), 0.9 A |

| Power consumption | 19.2 W |

| Cooling method | Natural air cooling |

| Dimensions | 120 mm(H) X 55 mm(W) X 110 mm(D) |

| Mass | 300 g |

| Max. no. of controllable axes | 8 |

Control functions | Sequence control

Motion control

(Electronic cam, electronic gear, linear interpolation, circular interpolation)

Robot control: NC function

(Cartesian coordinate, SCARA, and parallel link robots) | Sequence control

Motion control

(PTP control) |

| Control language | Programming languages conforming to international standard (IEC 61131-3) G-code (SMC200-A only) |

Dimensions [Unit: mm]

| SANMOTION C S200 Motion Controller Catalog |

Download Catalog

California | 27274 Via Industria, Suite B , Temecula, CA 92590 | 951-595-4200

Texas | 4545 Fuller Drive, Suite 240, Irving, TX 75038 | 972-719-5555

|