|

E-Motion Newsletter - September 2021 Renishaw Absolute Encoders

Company News - September 2021

Explore Renishaw Optical

Encoder Systems:

Let us talk about RESOLUTE™ today…

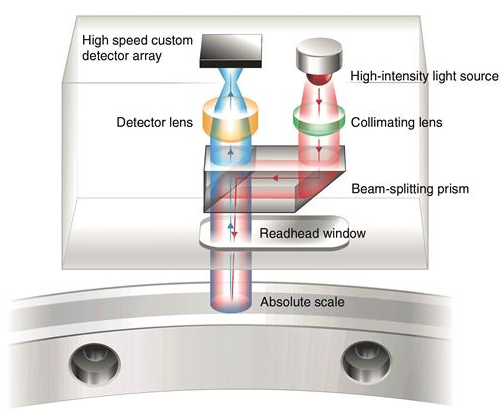

The process

begins...

The controller

initiates operation by sending a demand message to the readhead, instructing it

to capture the absolute position on the linear or rotary scale at that instant.

The head responds by flashing a high-power LED source to illuminate the scale.

The flash duration is as brief as 100 ns to minimize image blur on moving axes.

Crucially its timing is controlled within a few nanoseconds to preserve the

relationship between demanded and reported position, one of the essential

features that makes RESOLUTE ideally suited to very high specification motion

systems.

Single track

scale

The scale is

essentially a single track of full-width contrasting lines, based on a nominal

period of 30 µm. The absence of multiple parallel tracks gives important

immunity from yaw errors and much more lateral tolerance in head position.

Image

acquisition

The scale is

imaged, via an aspheric lens which minimises distortion, onto a custom detector

array designed specifically for RESOLUTE. The optical arrangement, with a

folded illumination path but direct imaging, is highly compact yet stable thus

assuring the fidelity essential for excellent metrology.

Data decoding

and analysis

Once captured

by the detector, the image is transferred via an analogue-to-digital converter

(ADC) to a powerful Digital Signal Processor (DSP). Specially developed

algorithms then obtain a true absolute, but relatively coarse position from the

code embedded in the scale. This process is checked, and corrections are made

by further algorithms in the DSP which exploit redundancy and intentional

restrictions in the scale code. Meanwhile other routines calculate a very high

resolution fine position, which is then combined with the coarse position to

provide a truly absolute and very high resolution location.

Final checks

and data output

After final

error checking procedures this information is uploaded in the appropriate

protocol to the controller as a pure serial word representing position to

within 1 nm. Protection against electrical noise disturbance is provided by

addition of a Cyclic Redundancy Check (CRC). The entire process can take as

little as a few microseconds and be repeated up to 25 000 times per second. By

a variety of techniques, including adjusting the light flash duration to the

axis speed, this performance is achieved at up to 100 m/s while, crucially,

preserving exceptionally low positional jitter at lower operating speeds.

And the result

is...

An encoder with generous installation tolerances: RESOLUTE

allows ±0.5° in yaw, pitch and roll and an impressive ±150 µm in rideheight.

Meanwhile the generous optical footprint and advanced error correcting

procedures confer excellent immunity to optical contamination, both particulate

and greasy smears. All this while maintaining 1 nm resolution at 100 m/s:

RESOLUTE is the answer to the toughest absolute challenge.

|