|

|

|

|

Beckhoff: TwinCAT 3 (TC1xxx Series)

TwinCAT 3 | eXtended Automation (XA)

Beckhoff created a global standard for automation with the launch of PC-based control technology in 1986. On the software side, the TwinCAT (The Windows Control and Automation Technology) automation suite forms the core of the control system. The TwinCAT software system turns almost any PC-based system into a real-time control with multiple PLC, NC, CNC and/or robotics runtime systems. TwinCAT 3 is the systematic further development of TwinCAT 2, with which the world of automation technology is being redefined. only one software for programming and configuration Visual Studio® integration more freedom in selecting programming languages support for the object-oriented extension of IEC 61131-3 use of C/C++ as the programming language for real time applications link to MATLAB®/Simulink® open interfaces for expandability and adaptation to the tools landscape flexible runtime environment active support of multi-core and 64-bit systems migration of TwinCAT 2 projects automatic code generation and project implementation with the TwinCAT Automation Interface

eXtended Automation Technology – TwinCAT 3 extends the standard automation world

eXtended Automation Architecture

supports all main fieldbuses supports IEC 61131, C/C++, MATLAB®/Simulink® supports Motion Control: from point-to-point to CNC supports TwinSAFE configuration supports Scientific Automation: robotics, measurement technology, Condition Monitoring

eXtended Automation Engineering one tool – Microsoft Visual Studio® integrated: IEC 61131 – worldwide standard in automation integrated: C/C++ – worldwide standard in IT integrated: TwinCAT System Manager – well-known configuration tool link to MATLAB®/Simulink®: worldwide standard in science expandable with other tools: editors, compilers TwinCAT 2 projects can be migrated. TwinCAT 3 modules: standardized programming frames using the .NET programming languages for non-real-time capable applications (e.g. HMI)

eXtended Automation Runtime IEC 61131, C/C++, MATLAB®/Simulink® objects in one runtime integrated TwinSAFE runtime extended real-time-functionality: min. 50 ìs cycle time and low jitter enhanced performance: support of multi-core CPUs future-proof: supports 64-bit operating systems

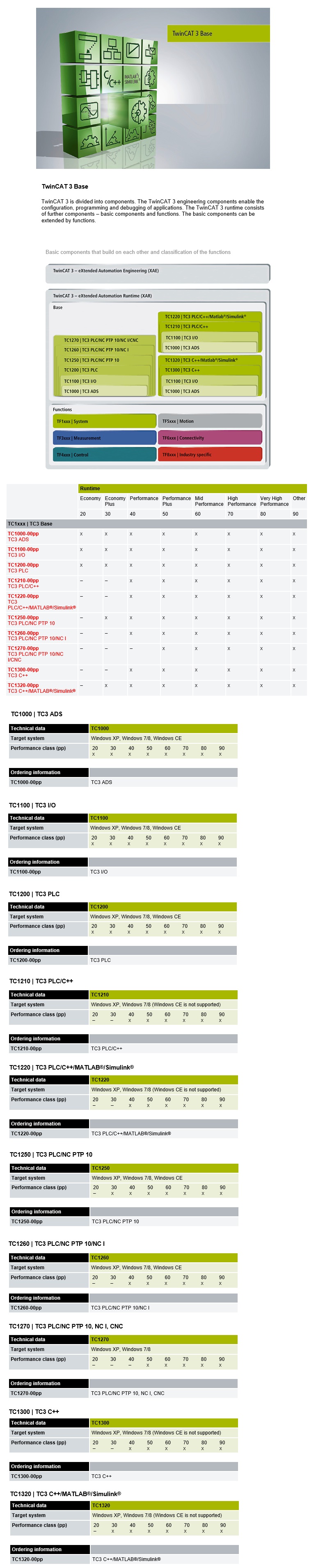

TwinCAT 3 is divided into components. The TwinCAT 3 engineering components enable the configuration, programming and debugging of applications. The TwinCAT 3 runtime consists of further components – basic components and functions. The basic components can be extended by functions. The TwinCAT Automation Device Specification (ADS) is the medium-independent protocol for the reading and writing of data and for instruction transmission within TwinCAT. In addition to the ADS router, ADS API interfaces and communication links for ADS Client in C/C++, .NET, Delphi, Java and WebServices are made available. ADS clients can be connected to TwinCAT controllers in the network via ADS. Using TwinCAT I/O, cyclic data can be collected by different fieldbuses in process images. Cyclic tasks drive the corresponding fieldbuses. Various fieldbuses can be operated with different cycle times on one CPU. Applications can directly access the process image. The fieldbuses and the process images are configured in TwinCAT Engineering. provides variable-oriented linkage of I/O devices to tasks tasks are variable-oriented among each other the smallest unit is one bit supports both synchronous and asynchronous relationships consistent exchange of data areas and process images online display in the directory tree online watch window "Force and Write" for commissioning and for testing task variables and I/O devices supported fieldbuses: EtherCAT Lightbus PROFIBUS DP (Master and Slave) Interbus CANopen SERCOS interface DeviceNet Ethernet USB SMB (System Management Bus)

TwinCAT PLC realizes one or more PLCs with the international standard IEC 61131-3 3rd edition on one CPU. All programming languages described in the standard can be used for programming. The blocks of the type PROGRAM can be linked with real-time tasks. Various convenient debugging options facilitate fault-finding and commissioning. Program modifications can be carried out at any times and in any size online, i.e. when the PLC is running. All variables are available symbolically by ADS and can be read and written in appropriate clients. process image size, flag range, program size, POU size and number of variables are limited only by size of RAM cycle times from 50 µs link time: typically 1 µs (Intel® Core™2 Duo) for 1,000 commands IEC 61131-3: IL, FBD, LD, SFC, ST, CFC online changes in programs and variables remote debugging via TCP/IP online connection with PLC runtime system worldwide via TCP/IP or fieldbus online monitoring of variables in variable lists, watch windows, editors online status and powerflow (accumulator contents) of programs and instances triggering, forcing and setting variables powerful debugging with single cycle, breakpoints, step in, step over, display of the current call stack, watchlist shows selection of variable, trace functions online management of all variable names and structures across the whole system remanent and persistent data, UPS supported storage on hard disk, storage in NOVRAM as option variable reading and writing access via ADS, OPC certified in accordance with PLCopen base level (IL/ST) structured programming with modular program management source code is stored in the target system convenient library management powerful compiler with incremental compilation all common data types, structures, arrays, including multi-dimensional arrays convenient creation of programs with: autoformat, autodeclare, cross-reference, search/replace, project comparison simple linking to source code administration tools by embedding in Microsoft Visual Studio®

Extension of the TwinCAT PLC TC1200 with additional C++ functionalities: online connection to PLC/C++ runtime system locally or worldwide via TCP/IP or via fieldbus online monitoring of variables in variable lists, watch windows and editors without setting break points online setting of variables

TC1220 | TC3 PLC/C++/MATLAB®/Simulink® Extension of the TwinCAT PLC/C++ TC1210 by the possibility to execute modules generated in MATLAB®/Simulink®: contains the TwinCAT 3 PLC and C++ runtime allows the execution of modules generated in MATLAB®/Simulink® multiple instancing of modules parameterisation of these modules at runtime online access to all parameters (can be deactivated) generic modules (no hardware connection necessary within the models) connection to the external mode of Simulink® connection to the TwinCAT C++ debugger, with graphical representation of the blocks modules can be called from other modules or directly by tasks

TC1250 | TC3 PLC/NC PTP 10 Extension of the TwinCAT PLC TC1200 by the possibility to realize point-to-point movements in software (TwinCAT Motion Control PTP 10). The axes are represented by axis objects and provide a cyclic interface, e.g. for the PLC. This axis object is then linked to a corresponding physical axis. In this way the most diverse axis types with the most diverse fieldbus interfaces can be connected abstractly with the axis objects, which always offer an identical configuration interface. The control of the axes can be configured in various constellations (position or velocity interface) and various controllers. The axes are configured in TwinCAT Engineering. up to a maximum of 255 axes on one CPU supports electrical and hydraulic Servo Drives, frequency converter drives, stepper motor drives, DC drives, switched drives (fast/slow axes), simulation axes and encoder axes supports various encoders such as incremental encoder, absolute encoder, digital interface to the drives such as EtherCAT, SERCOS, SSI, Lightbus, PROFIBUS DP/MC, pulse train standard axis functions such as start/stop/reset/reference, velocity override, master/slave couplings, electronic gearbox, online distance compensation Programming is carried out via PLCopen-compliant IEC 61131-3 function blocks convenient axis commissioning options online monitoring of all axis state variables such as actual/set values, releases, control values online axis tuning forcing of axis variables configuration of all axis parameters, such as measuring system, drive parameters and position controller configurable controller structures: P control, PID control, PID with velocity pre-control, PID with velocity and acceleration pre-control online master/slave and slave/master conversion flying saw (diagonal saw [optional]) cam plates (support by TC3 Cam Design Tool [optional]) FIFO axes (optional) external set value generators multi-master coupling

TC1260 | TC3 PLC/NC PTP 10/NC I Extension of the TwinCAT PLC/NC PTP 10 by the possibility to realize movements with up to three interpolating and up to five auxiliary axes. Various axis types with various fieldbus interfaces are supported. The movement is usually programmed in DIN 66025, but it can also alternatively be carried out via PLC function blocks. max. 3 path axes and up to 5 auxiliary axes per group 1 group per channel, max. 31 channels supports electric servo axes, stepper motor drives interpreter functions such as subroutine and jump technology, programmable loops, zero point shifts, tool corrections, M and H functions geometry functions: straight lines and circles in 3-D space, circles at all main levels, helices with base circles at all main levels, linear, circular and helical interpolation at the main levels and freely definable levels, Bezier splines, look-ahead function online reconfiguration of axes in groups, path override, slave coupling to path axes, auxiliary axes, axis error and sag compensation, measuring functions programming in DIN 66025 access alternatively via function blocks according to IEC 61131-3 operation of automatic mode, manual mode (jog/inch), single block mode, referencing, handwheel mode (movement/overlay) convenient debugging with online monitoring of current set/actual position (position lag of all axes), NC program line currently being processed, NC program line currently being interpreted, channel status support of kinematic transformations in combination with TF511x

TC1270 | TC3 PLC/NC PTP 10, NC I, CNC Extension of the TwinCAT PLC/NC PTP 10 by the possibility to realize an interpolation with up to 32 simultaneously interpolating axes. The number of axes and/or the number of channels can be adapted to the requirements of the application via the option packages. Various transformations can be supplemented via option packages. Programming takes place according DIN 66025. The axes and channels are configured in TwinCAT Engineering. 8 path axes/controlled spindles, max. 64 axes/controlled spindles (optional), max. 12 channels (optional) supports electric servo axes, stepper motor drives subroutine and jump technology, programmable loops, zero point shifts, tool corrections, M and H functions, mathematical functions, programming of parameters/variables, user macros, spindle and auxiliary functions, zero point shifts, tool functions geometry functions: linear, circular and helical interpolation at the main levels and freely definable levels, max. 32 interpolating path axes per channel (optional), look-ahead function axis functions, coupling and gantry axis function, override, axis error and sag compensation, measuring functions programming in DIN 66025 with high-level language extension access via function blocks from TwinCAT PLC according to IEC 61131-3 operation with automatic mode, manual mode (jog/inch), single block mode, referencing, block advance, handwheel mode (movement/overlay) convenient debugging with online monitoring of all states

The TwinCAT 3 C++ runtime environment enables the execution of real-time modules written in C++. The following functions are supported, among others: online connection to C++ runtime system locally or worldwide via TCP/IP or via fieldbus online monitoring of variables in variable lists, watch windows and editors without setting break points online setting of variables

TC1320 | TC3 C++/MATLAB®/Simulink® Extension of the TC1300 by the possibility to execute modules generated by MATLAB®/Simulink®. contains the TwinCAT 3 C++ runtime allows the execution of modules generated in MATLAB®/Simulink® multiple instancing of modules parameterisation of these modules at runtime online access to all parameters (can be deactivated) generic modules (no hardware connection necessary within the models) connection to the external mode of Simulink® connection to the TwinCAT C++ debugger with graphical representation of the blocks modules can be called from other modules or directly by tasks

Model No.: TC1000-00pp, TC1100-00pp, TC1200-00pp, TC1210-00pp, TC1220-00pp, TC1250-00pp, TC1260-00pp, TC1270-00pp, TC1300-00pp, TC1320-00pp

|

|

|

|

|

|

|